Hydrothermal feeds

In the feed production we proceed from simple and traditional natural processes.

The aim of using our feed is to improve the economy and health in livestock production.

-

What is hydrothermal processing?

Hydrothermal treatment is a process where the grain is heat-treated and its structure is mechanically disturbed.

-

What is happening with the grain?

During the process of hydrothermal flocking the physicochemical and chemical properties of cereal grains change.

-

What is happening in the animal's body?

Several crucial processes take place in the animal’s digestive tract while the the animal is digesting hydrothermically treated grain.

-

What is the effect on animal production?

Better digestibility – better health – better performance – better economic results.

What is hydrothermal processing?

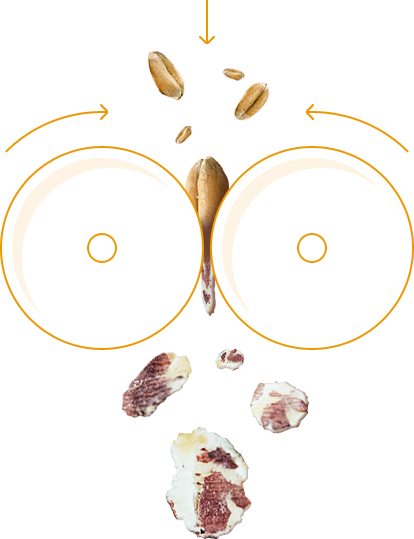

The grain is steamed at a temperature of 70-100 ° C according to the treated grain, and then, when passing between two rollers, it crushes. By combining the temperature, humidity, pressure and compression time, a new final product is created. The properties of such processed cereals and legumes are significantly different from traditional feed materials.

What is happening with the grain?

During the process of hydrothermal flocking the physicochemical and chemical properties of cereal grains change.

Steaming of grains at temperatures 70-100°C

The temperature of steam leads to the elimination of pathogenic microorganisms (E. coli, salmonella) and the destruction of mould and yeast spores. The hydrothermal flake is a highly hygienic, stable feed.

Gelatinization and Dextrinization

To increase the digestibility of individual nutrients, especially starch, it must work synergistically: wet heat in combination with mechanical breakdown of the grain structure (protein matrix and starch granules.

Mechanical change of grain structure in flakes means breaking the matrix of proteins that cover starch granules, making the nutrients available for their easy and perfect digestion.

What is the production process like?

The production process takes place in the following steps

-

Storage and cleaning

-

WATERING

-

STEAMING

-

FLAKING

-

COOLING AND DRYING

Hydrothermal feed is suitable for

What is happening in the animal's body?

Several crucial processes take place in the animal’s digestive tract while the the animal is digesting hydrothermically treated grain.

-

Starch is significantly made available for rumen microorganisms and enzymes in the small intestine

-

Gradual rumen fermentation promoting chewing and rumen buffering

-

The number of rumen microorganisms is growing and more microbial protein is formed

-

Feed nutrients are highly digestible

-

Loss on ungraded nutrients decreases substantially

For adult animals with fully developed gastric mills, the flakes are enriched with urea , which provides the digestive microorganisms with the necessary nitrogenous substances.

As the digestibility of starch, proteins and fat is substantially increased, the feeding value of the grain with the hydrothermal treatment is considerably higher than that digestibility of the native grain, and due to the structure the nutrients are released in time. Flakes can be used to feed all livestock animals.

What is the effect on animal production?

Especially economic. Livestock nutrition is also an investment in future breeding results.

There are simple rules:

-

Better digestibility

-

Better health condition

-

Better performance

-

Better economic performance